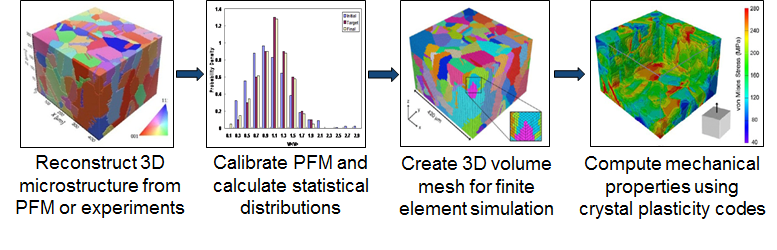

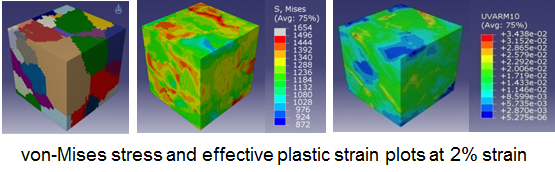

| Linking Phase Field and FEM Modeling for Process-structure-Property Predictions | Microstructure

based modeling techniques can be used to reduce development costs of

new materials and to better understand their mechanical behavior. The

purpose of this research is to develop an approach to microstructure

sensitive design that links phase field and finite element modeling to

achieve a more complete coupling between the process-structure-property

relationships. The

methodology consists of four steps: microstructure reconstruction,

statistical analysis, mesh development, and microstructure-sensitive

FEM. The approach has been demonstrated for a Ni-base superalloy utilizing a 3D microstructure obtained through multi-section electron backscatter diffraction.

|

| Cellulose-based Nanocomposites as a Potential Scaffold in Cardiovascular Tissue Engineering | Cardiovascular

diseases are the leading cause of death worldwide. Tissue engineering

as a potential candidate to revascularize a diseased vessel has been

under extensive research study over the past few decades. As a major

component, scaffold material plays a significant role for such a

platform to be successful.

The objective of the current research is

to design a fully cellulose-based nanocomposite with an improved

supermolecular structure to potentially introduce a biomaterial

scaffold for cardiovascular tissue engineering.

Methodology:

Fabricating

cellulose nanofibers (CNW) through a multistage procedure consists of

an acid hydrolysis, a few cycles of centrifugations, a dialysis

exchange against distilled water, and a freeze-drying of fibers. Then

pre-dispersing the nanofibers prior to mixing with cellulose acetate

(CAP) matrix to form the final nanocomposite.

|